Traction Engines of various types,

and the Lombard Steam Log Hauler

There was a type of steam locomotive commonly used between 1860 and 1940, that

did not run on rails but had huge steel wheels for use on good sealed roads,

unmade country roads, or in paddocks. They were used for ploughing fields,

road-making, haulage of loads too heavy for horse teams or bullock teams,

and general delivery work. They were known as "traction engines", and as

roads improved, they became more refined, and were often called "road

locomotives".. They were quite heavy, being from 4 to 12 tonnes in weight on

average, although some American examples made by Case or Avery were bigger

and heavier than the European versions. Many were fitted with smooth rolls

on the rear wheels and the front wheels were replaced with a single wide

roll (in two sections) so that all wheels could roll and flatten out a

section of road as wide as the whole machine. These versions were called

"steam rollers" and could still be seen at work into the 1960s.

Three steam rollers of the 1920s. Front: Fowler of 1923. Behind it: Aveling and Porter of unknown date. A third roller is at left rear.

.jpg)

A typical small English traction engine of around 1910 built by John Fowler and Co. Its rear wheels are fitted with solid rubber tires for use on sealed roads.

A typical large English traction engine of 1916 built by John Fowler and Co. Its rear wheels are fitted with steel strakes for use in fields. The boiler is low-slung; the engine and flywheel are mounted on top of it.

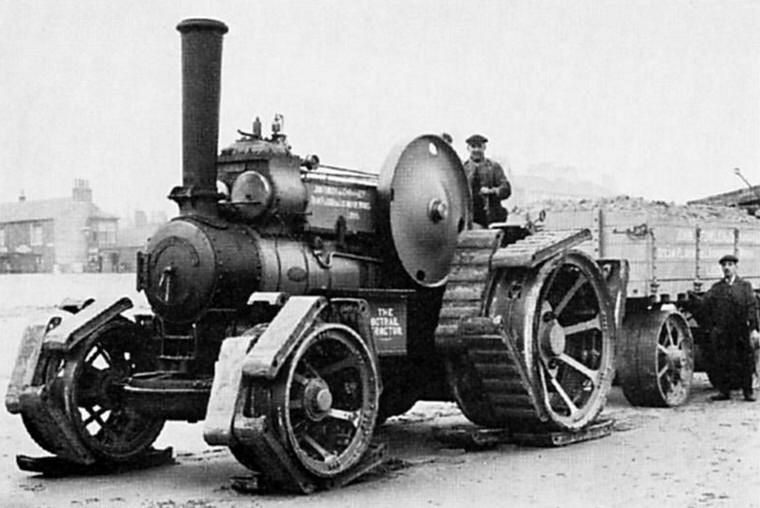

This is an attempt to improve an engine's traction in the muddy fields of Flanders during World War I using multiple 'feet' which allowed four 'feet' per rear wheel to be in contact with the ground at any one time.

This is a larger Fowler engine also dating from World War I. This attempt to improve an engine's traction in mud during World War I uses eight large 'shoes' per wheel instead of individual 'feet', and had only limited success.

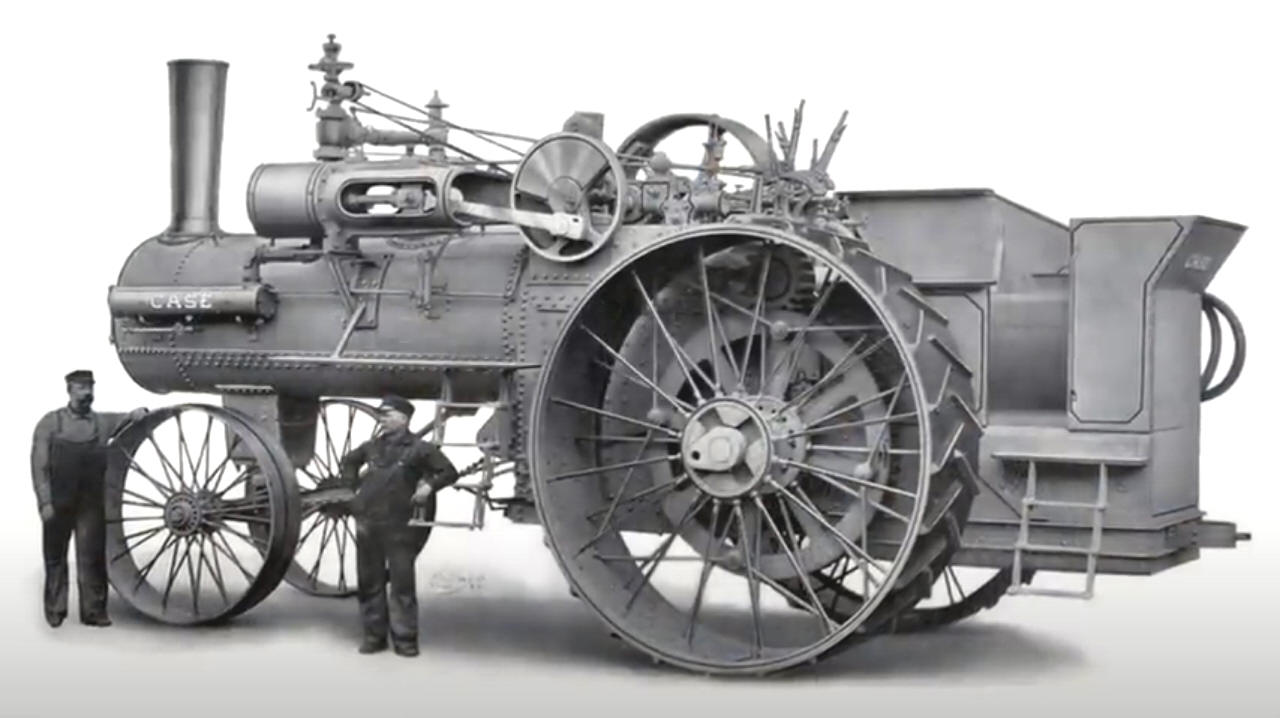

This is an example of the largest traction engine ever built. It is American, a Case 150 HP machine. It was too powerful for the steel used to make its gears, which rapidly wore out or failed, so Case concentrated on selling their more reliable 110 HP model instead. Only nine of these monsters were produced until their production ended in 1907. Many men could walk underneath the boiler without stooping.

This is probably the only Case 150 HP surviving in working order, but it is a replica. The engine and flywheel are mounted above the boiler, and it has two speeds, giving top speeds of 2.64 miles per hour in low and 5.69 miles per hour in high. There are numerous smaller Case traction engines still in existence, many being fully operational. Watch the video. Watch a Case 150 climb a 30º grade here.

This is another American engine, in this case an Avery 30-50 HP model. The first models from this company had a low-slung boiler with the cylinders and motion mounted on top (called "Overtype"), but later models such as the one pictured had a high-mounted boiler with the cylinders and motion mounted underneath it, railway style or "Undertype" or "Undermounted". The high-mounted boiler with its railway-type fittings such as the headlight, chimney, steam dome and enclosed cab give it a distinctive railway locomotive appearance. This is accentuated by the mounting of the cylinders underneath the smokebox, together with the slide bars, crossheads, connecting rods, crankshaft and valve motionwork. There the resemblance ends, for there are two steerable wheels at the front of the mainframe, and two huge driving wheels underneath the crew's cab. Between the crankshaft and the driven rear wheels is the gearing mechanism used to transfer power to the back axle. Watch the video.

With regards to logging:

Steam traction engines were popular in Britain, Commonwealth countries and some parts of Europe, but American versions were large and heavy, and unsuited to logging operations in steep and rugged country, being prone to becoming bogged and then very difficult to extricate. Alvin Orlando Lombard designed a new type of steam-powered logging tractor which had a locomotive-type boiler like the larger Avery models, firebox and cab, with a set of two cylinders under the smoke-box. These drove via a shaft and gears a fixed power unit under the cab and firebox which had four cogged wheels. Lombard's innovation was to develop a set of tracks on either side which connected the cogged wheels on that side. Alvin called this vehicle his "Lombard Steam Log Hauler", and its use of what were called 'caterpillar tracks' was very successful, and soon adapted to other heavy vehicles. He was granted a patent in 1901 for "the first successful application of a continuous track for vehicle propulsion", and his idea was later used in World War I for use with military tanks, and later with earth-moving equipment such as bulldozers.

As the tracks on both sides were powered as a unit by the steam engine, and the wheels were fixed to each other by solid axles, a method of steering had to be found. The version below shows two men steering the vehicle from a seat on the front platform, which was could be covered by a weather-proof shelter in cold weather. Many steersmen preferred to do without the shelter, for if the vehicle ran way, and a collision was imminent, they would need to jump off, and the shelter might impede their escape. One person could manage the steering only if the road were smooth and firm. A communication cord which ran back along the boiler to the whistle enabled the steersman to warn the driver to shut off steam and stop at once if there was an emergency (see the fifth picture below). Coal or wood fuel were carried in a bunker behind the cab, which was occupied by a driver and fireman. Water was carried in a large tank which sat atop the boiler between chimney and cab, such a tank being called a "saddle tank"

In summer, such an engine could drag three or four sleds through the forest. Another crewman rode on the sleds, also with a communication cord to warn the driver if anything untoward was happening. The later models of the Lombard Steam Log Hauler could pull eight or more sleds. The record train length was 24 sleds with a total length of 500 metres. Going downhill had to be tackled with care, in case the sleds began to jack-knife or overrun the engine.

In winter the front wheels were removed and replaced by a pair of skis beneath the steering platform. That was when hauling logs from the forest was at its most dangerous, cold and slippery. The Log Haulers continued to be used until the early 1930s, and at least ten have survived.

Watch the video.

Watch the video.

The steersman pulls the communication cord - note steam from the whistle on the side of the steam dome.

Note weather protection in the cab and the steersman's shelter.

Hauling logs in winter.

Watch the video.

Watch the video.

Is this the first steam-powered snowmobile ?